Most people think that process cooling is simple. Water cools off hot things.

But if it is so simple, why do so many of our customers have cooling issues? The concepts behind cooling systems are simple. Putting those concepts together and building a system can be tricky.

In this article, we review the basics of process cooling and components of cooling systems.

Calculations

Heat transfer is the basis of any cooling process. For plastics, it is the transfer of heat from your process (TProcess) to cooling water (Twater). The load of a system follows the calculation below. This load is dependent on the flow rate and difference in Twaterand Tprocess.

Load (btu/hr) = Specific Heatwater x Densitywater x ratewater x (Tprocess. - Twater)

Cooling Systems

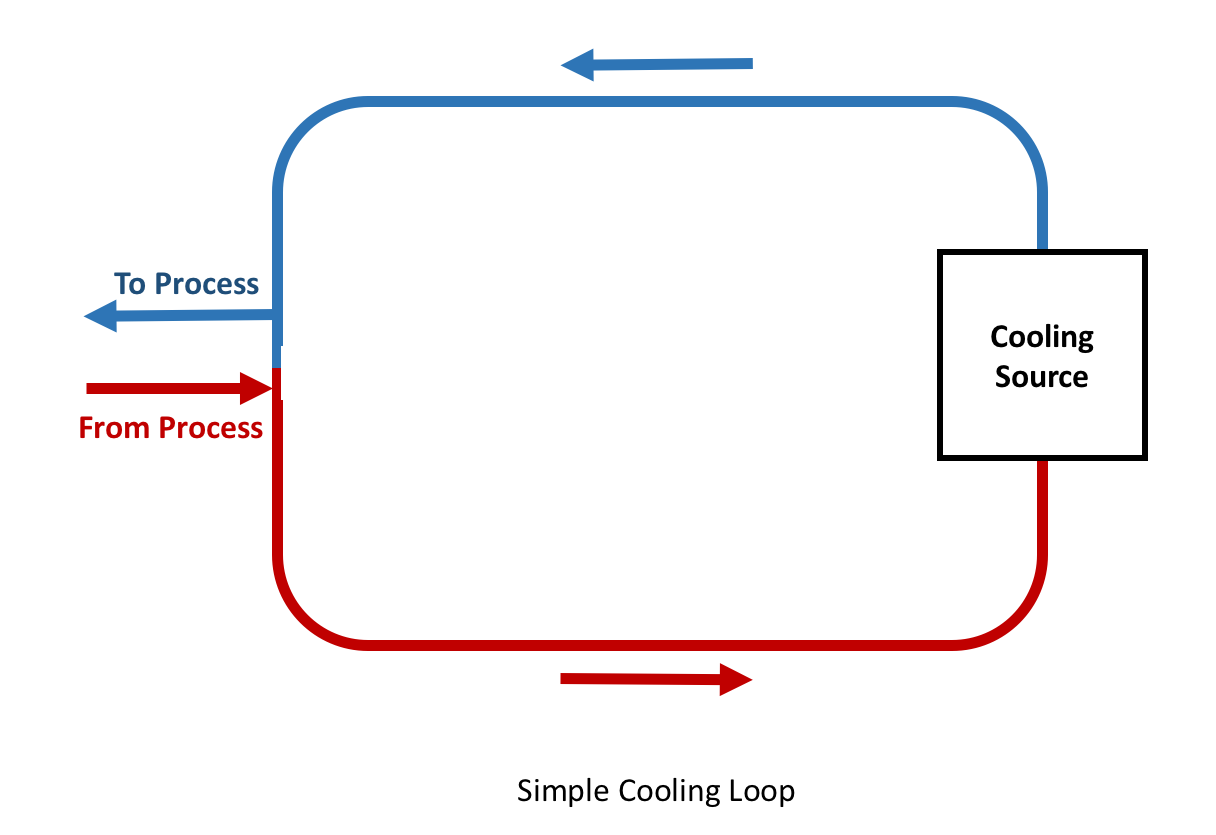

In most applications, cooling systems have a standard setup. A cooling source provides cooled water that flows around a loop and supplies it to a process.

Adding more components and processes makes these systems more complex.

Cooling Source

The cooling source required depends on required temperature, climate, and process. Most commons sources are cooling towers and chillers.

There are several types of chillers including water-cooled and air-cooled. They can be large, plant-wide systems or smaller modular units.

Cooling Loops

After cooling the water, it is delivered to the process using a cooling loop. Water is pumped through a circuit to the process and back to the cooling source.

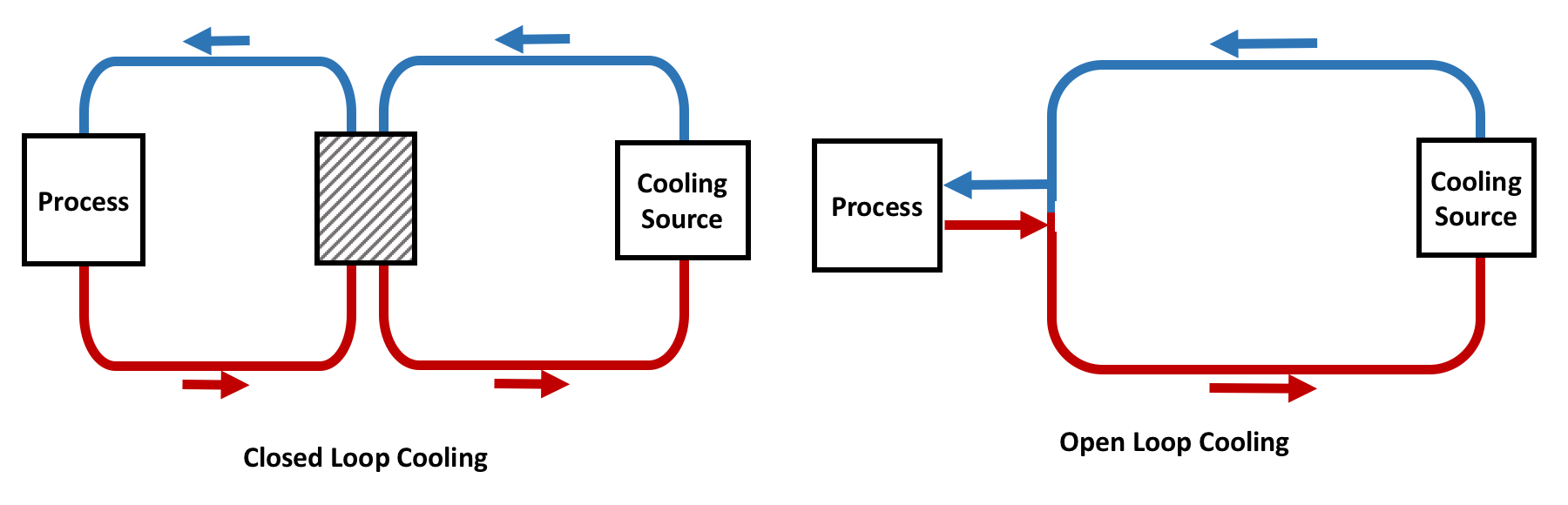

There are two types of cooling loops: closed and open. Closed loops are separate from the process it is cooling and utilize a heat exchanger to transfer heat. Open loops pump water through the process and remove the heat directly.

Turbulent Flow

People often make the mistake of thinking that more water is always better. The thought being "if 10 gallons/min is doing this well then 20 gallons/min must be better".

This is not always true because the rate and pressure at which water is flowing through pipe effects how it flows.

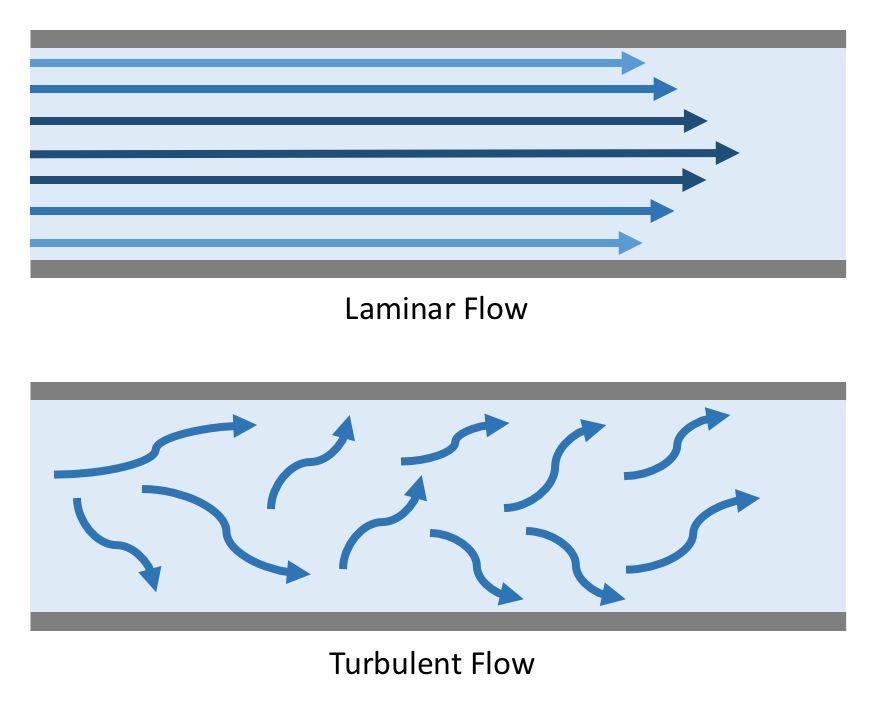

Water can flow through piping in both turbulent and laminar flow.

If you are using water to cool, then you want turbulent flow. Turbulent flow allows more surface contact between the pipe walls and water. More surface contact means more efficient heat transfer.

People often completely open valves and size (or oversize) pumps to maximize the flow of water through their pipes. Too much water creates laminar flow and reduces the heat transfer capability of their system.

Specifying a System

Process cooling is not as simple as getting a couple of pumps, some pipe, and a chiller. Many factors go into specifying the correct system for an application. Below are some simple questions to keep in mind when looking for a cooling system.

What is the load of your system?

- process

- materials

- throughput

What is the desired supply temperature?

- chillers (45-55F)

- towers (80-85F)

Adams Engineers partners with Thermal Care to help our customers with process cooling. If you have any questions or would like us to review your system, please contact us. See our products for more about Thermal Care.