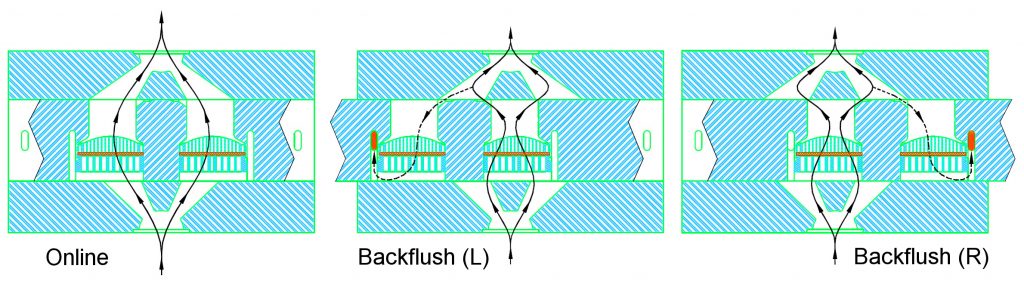

Backflush Continuous Screen Changers (CSC-BF) filter contaminated polymer melt streams typical of post-industrial and post-consumer plastic scrap. As contaminants build up on the screen pack, a pressure setpoint or timer initiates backflush operation. The fully automated process efficiently lifts and evacuates impurities from the screen surface before indexing the screen back into service.

Uninterrupted melt filtration is achieved using four (4) online screen pockets. During backflush or screen change, seventy-five percent (75%) of the available filter area remains online. This effectively lowers average extruder back pressure and yields higher production output as well as benefiting extruder life and reducing energy. Each screen is self-cleaned in sequence as needed until the backflush process can no longer effectively remove embedded contaminants and a screen change is signaled.

Backflush frequency varies with contamination levels and line pressure. Screen packs are typically self-cleaned 20-25 times or more, saving screen costs and labor between screen changes and maintaining continuous operation throughout. The rugged, low-maintenance design has no mechanical valves or seals and can operate leak-free for decades with proper care.

| Temperature °F [°C] | Up to 650 [343] |

| Max oper. pressure PSI [bar] | max. 7,500 [517] |

| Control zones (housing) | Four (4) |

| Heating | Electric/Fluid |

| Model | Max. Throughput* | Screen Diameter | Filter Area | |||

| Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | |

| CSC-125BF | 3,100 | 1,405 | 4.93 | 125.3 | 4 x 19.1 | 4 x 123.2 |

| CSC-148BF | 4,400 | 2,000 | 5.84 | 148.3 | 4 x 26.8 | 4 x 172.6 |

| CSC-176BF | 6,600 | 2,995 | 6.94 | 176.3 | 4 x 37.8 | 4 x 244.1 |

| CSC-200BF | 8,400 | 3,810 | 7.88 | 200.3 | 4 x 48.7 | 4 x 314.4 |

| CSC-230BF | 11,500 | 5,215 | 9.07 | 230.3 | 4 x 64.5 | 4 x 416.3 |

| CSC-250BF | 19,400 | 8,800 | 9.85 | 250.3 | 4 x 76.1 | 4 x 490.8 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | ||||||

More details