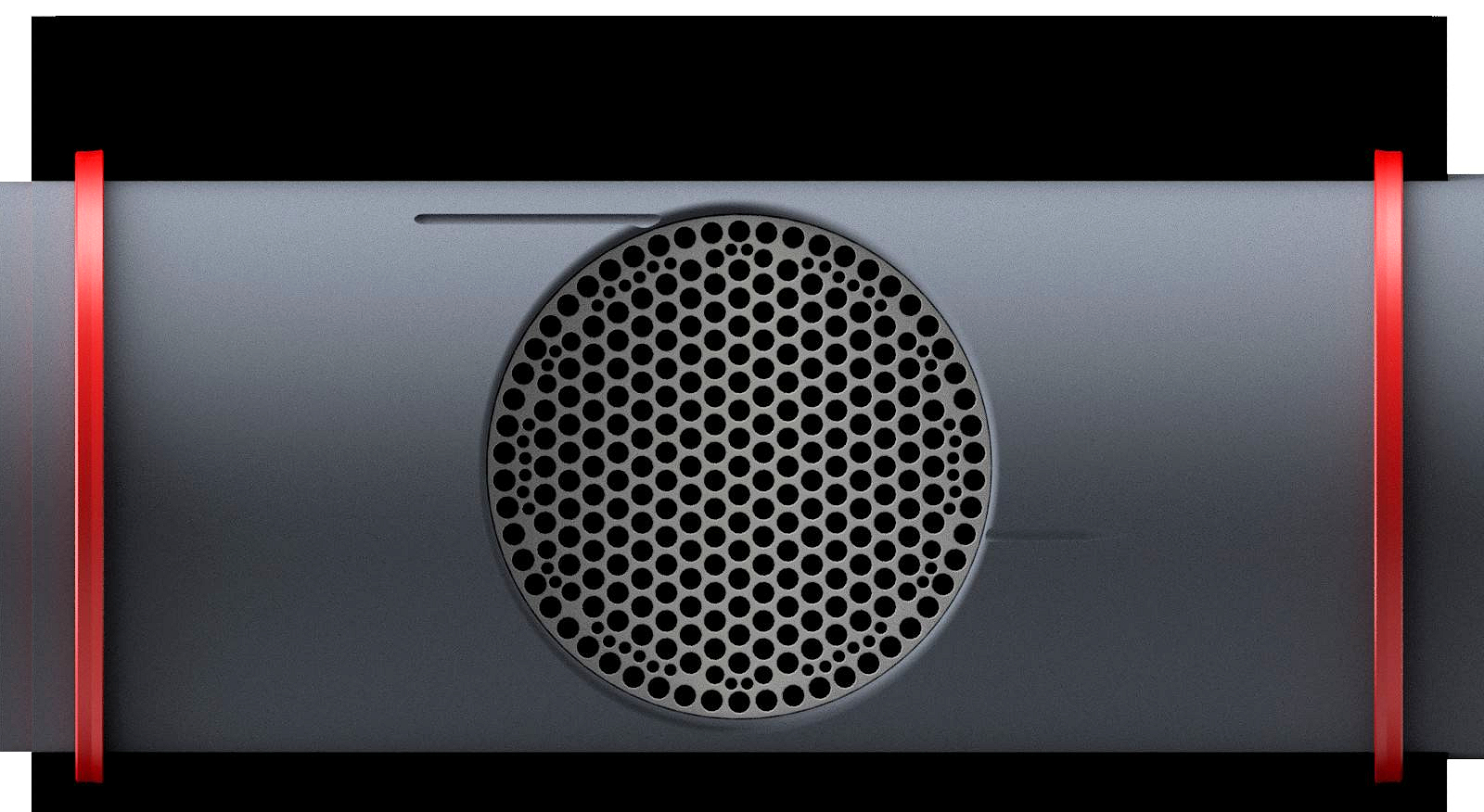

The Discontinuous Screen Changer (DSC) provides convenient, easy access melt filtration for polymer and hot melt adhesive batch operations. The design features a single filter pocket machined into a cross-bolt. Shifted offline only for momentary screen change, the easy-to-clean filter pocket has no hang-up areas and features a streamlined flow channel for fast material or color changes without cross-contamination. The self-sealing design has no mechanical parts to wear out or replace. Maintenance is reduced to periodic cleaning of the cross-bolt.

An optional patented seal insert allows the Discontinuous Screen Changer to filter materials with viscosities as low as 10 centipoise / 1800 MFI without risk of leakage. The design can also accommodate an integral divert for batch operation startup or changeover.

| Temperature °F [°C] | Up to 600 [315] |

| Max oper. pressure PSI [bar] | max. 7,500 [517] |

| Control zones (housing) | One (1) |

| Heating | Electric |

| Round Screen | Max. Throughput* | Screen Diameter | Filter Area | Heater | Weight | ||||

| Model | Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs |

| DSC-058 | 375 | 170 | 2.3 | 58.3 | 4.1 | 26.7 | 2.0 | 150 | 68 |

| DSC-076 | 650 | 295 | 3.0 | 76.3 | 7.1 | 45.7 | 4.0 | 267 | 121 |

| DSC-096 | 1,000 | 455 | 3.8 | 96.3 | 11.3 | 72.8 | 4.0 | 266 | 121 |

| DSC-116 | 1,500 | 680 | 4.6 | 116.3 | 16.5 | 106.2 | 4.0 | 415 | 188 |

| DSC-125 | 1,800 | 910 | 4.9 | 125.3 | 19.1 | 123.3 | 6.0 | 477 | 216 |

| DSC-148 | 2,400 | 1,090 | 5.8 | 148.3 | 26.8 | 172.7 | 12.0 | 1,325 | 601 |

| DSC-176 | 3,500 | 1,590 | 6.9 | 176.3 | 37.8 | 244.1 | 12.0 | 1,335 | 606 |

| DSC-200 | 4,500 | 2,040 | 7.9 | 200.4 | 48.9 | 315.4 | 24.0 | 2,025 | 919 |

| DSC-230 | 6,000 | 2,720 | 9.1 | 230.3 | 64.6 | 416.5 | 24.0 | 2,912 | 1,321 |

| DSC-250 | 8,000 | 3,630 | 9.9 | 250.3 | 76.3 | 492.0 | 24.0 | 3,250 | 1,597 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||

| Oval Screen | Max. Throughput* | Screen Diameter | Filter Area | Heater | Weight | ||||

| Model | Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs |

| DSC-125/170 | 2,500 | 1,090 | 4.92 x 6.69 | 125 x 170 | 27.7 | 179.0 | 6.0 | 850 | 386 |

| DSC-148/230 | 4,100 | 1,500 | 5.71 x 9.06 | 145 x 230 | 44.7 | 288.4 | 12.0 | 1,325 | 601 |

| DSC-176/270 | 5,800 | 2,585 | 6.87 x 10.63 | 175 x 270 | 63.1 | 406.8 | 18.0 | 1,090 | 495 |

| DSC-200/300 | 7,500 | 4,400 | 7.87 x 11.81 | 197 x 300 | 79.7 | 514.1 | 24.0 | 2,695 | 1,223 |

| DSC-230/310 | 9,000 | 5,990 | 9.06 x 12.20 | 230 x 310 | 92.9 | 599.5 | 24.0 | 3,580 | 1,624 |

| DSC-250/345 | 12,000 | 9,980 | 9.84 x 13.58 | 250 x 345 | 112.9 | 728.3 | 24.0 | 3,580 | 1,624 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||

Options

Special patented seal for ultra-low viscosity materials (click for info)

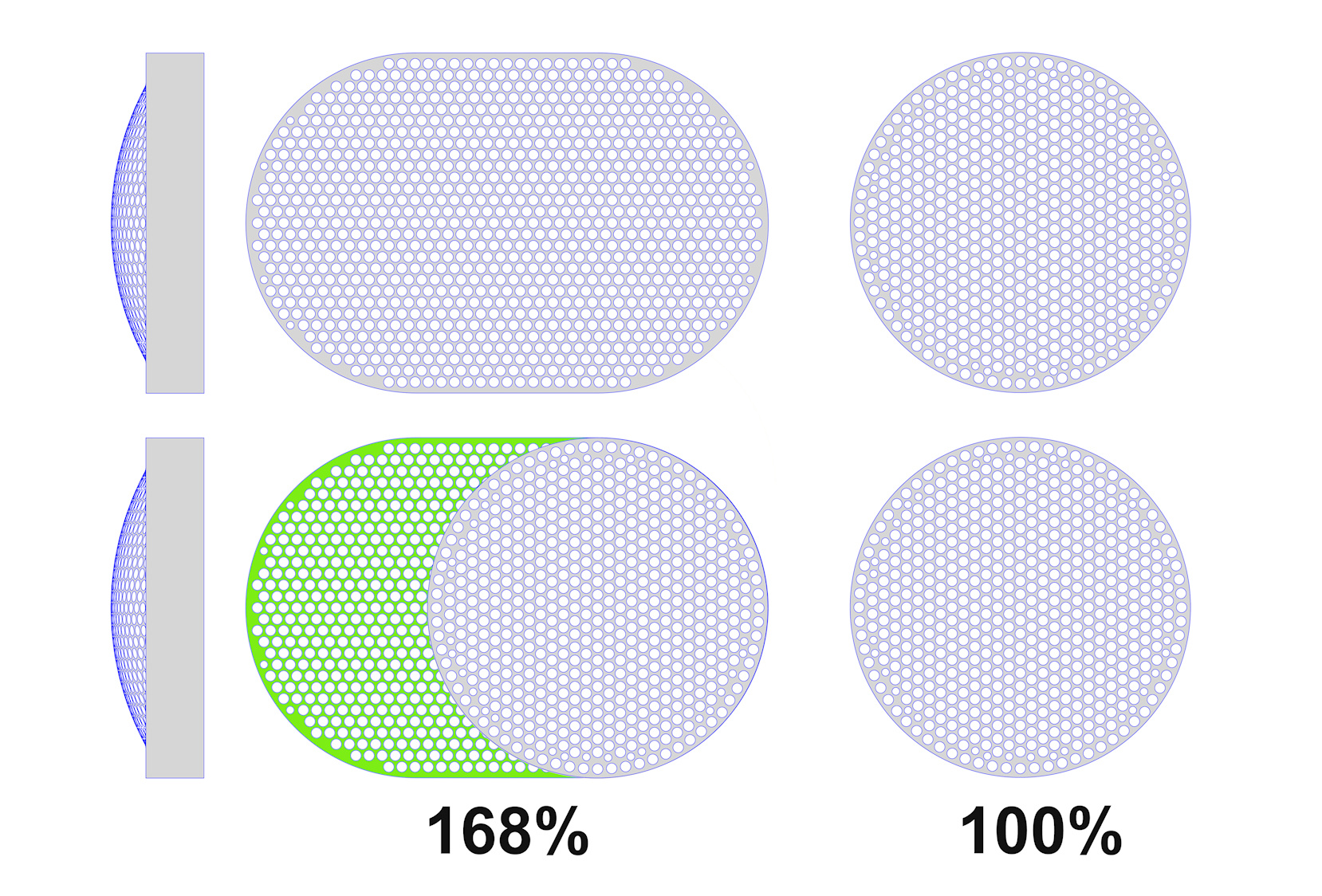

Oval pockets add more filter area, lower delta-P, and more output (click for info)

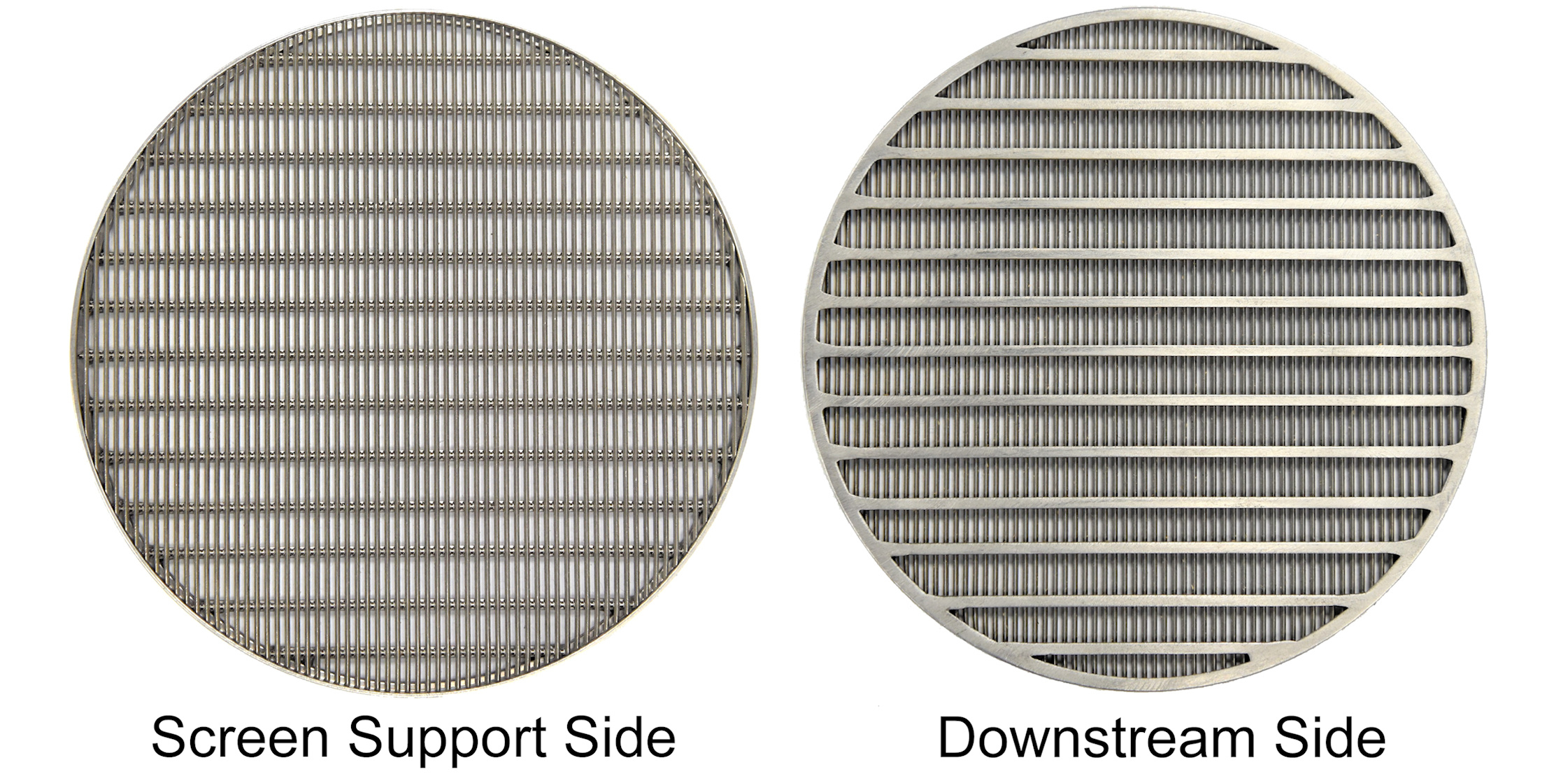

Super plates for improved screen efficiency (click for info)

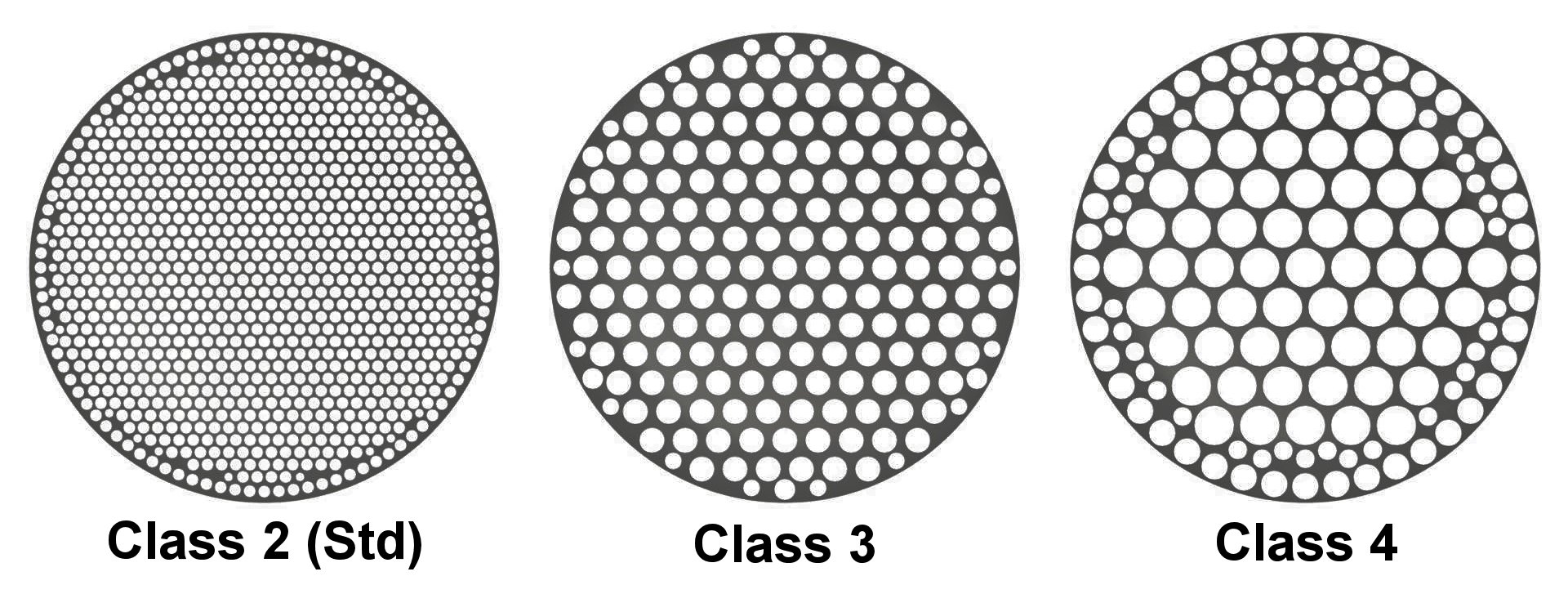

Larger breaker plate holes for pressure drop reduction (click for info)

Plus

Accessories